On-Demand Manufacturing: The Perfect Way to Minimize Your Risk

This process takes time and manpower. Furthermore, the manufacturing process lacks the transparency companies want and need. When a startup or small and medium enterprise moves through this process, they often find they detour from the innovation path. Fortunately, they don’t need to take this route. With the help of on-demand manufacturing, often referred to as cloud manufacturing, companies find they have the items they need and stay on track with their business goals.

What is On-Demand Manufacturing?

With on-demand manufacturing, a company only produces the goods it needs at any given time. They can request one copy of the product or 1,000. This process allows companies of any size to provide their customers with the desired product in a reasonable time frame. Startups and SMEs find this is the solution they need to build their business and expand it.

Why Choose On-Demand Manufacturing Over Traditional Options?

Companies want to know the benefits of cloud manufacturing to ensure it meets their needs. They find the process is scalable and allows them to manufacture only those items they know will sell. They no longer need to sit on inventory and pay for storage space for the products or markdown items that didn’t sell as expected. Furthermore, customers love getting a product they need promptly while paying an affordable price for it. There is also no need for the company to produce parts that will sit around waiting to be used, as they can be manufactured only when they are required to fulfill a sale.

The company can expand its product line and create unique, one-of-a-kind items. In addition, they find the need to forecast new product volumes decreases, and they can dedicate staff resources to those tasks designed to grow the business. Customer service improves as a result.

Less Risk

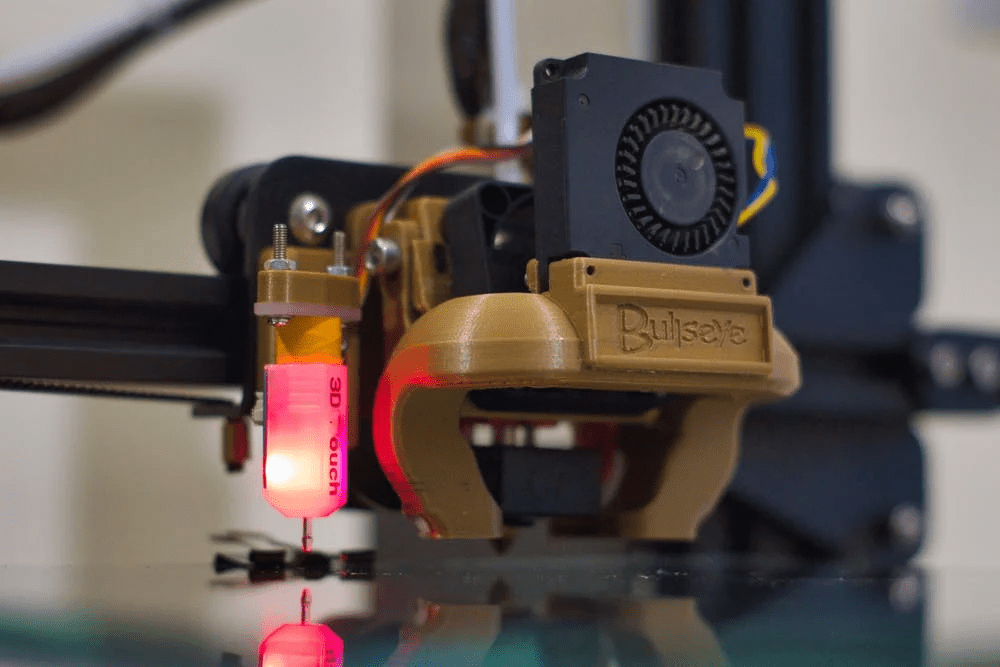

Companies take on less risk thanks to on-demand manufacturing. In addition, 3D printing costs continue to decrease, manufacturing industries are modernizing, and consumers love personalized products. Startups and small to medium size enterprises benefit from on-demand manufacturing, as they employ a risk reduction strategy. What are some benefits associated with this option?

Customization

Customization options increase with cloud manufacturing, as the business finds it can make small production runs. Customization options boost a company’s sales conversions. Furthermore, companies find they can make prototypes without incurring the high cost of doing so. Prototypes often become cost-prohibitive when traditional manufacturing methods are used, but on-demand manufacturing allows a company to make a prototype at an affordable cost. The company can then determine its market acceptance and determine whether to proceed with manufacturing the item.

Time to Market

Traditional manufacturing methods lead to a lag time between obtaining the initial quote to producing the item. By the time a product makes it to market, the demand for the item could significantly decrease. Startup and small to medium enterprise businesses often find this to be a major issue. They forecast major sales for a product only to find large sums of money are tied up in products that don’t move. Faster production methods enable a business to help more customers and generate more revenue without this risk.

Decreased Costs

The cost assessment takes less time and the estimation process is simplified. The fast production times result in a rapid lead time. Businesses find this reduces their sales risk significantly. Business owners find they no longer need to place a minimum order to work with suppliers. This saves them time and money as well.

Inventory and storage costs drop drastically when a company makes use of on-demand manufacturing. Companies just starting out and small businesses need to maximize their cash flow, and on-demand manufacturing allows them to do so. They reduce the capital spent on storage, as they pay less in warehouse fees and the labor required to manage the storage. The funds saved in this area may be used for marketing, customer service, research and development, and more. All help to grow the business further.

Furthermore, the funds saved in this area may be kept in reserve. Many business owners find they have little in reserve when disaster strikes. The global pandemic of 2020 showed how important it is to prepare for anything and have funds set aside for when a problem arises. Reduced inventory requirements free up funds that become valuable in times such as those.

Transformation

Cloud manufacturing makes use of a platform-based approach. This approach continues to transform the manufacturing industry in ways people couldn’t have imagined a few short years ago. It finds ways to reduce the frustration experienced by designers and engineers in a variety of areas.

The platform provides an interface that is automated and centralized. This platform allows for simplified communication between the engineers and suppliers while eliminating delays and inefficiencies. The streamlined communication process offers countless benefits and eases the production process at every step.

Companies find they can produce products in the U.S. today that previously weren’t possible. In the past, electronic part production runs were handled offshore for a range of reasons. Today, companies in the United States take on PCB assembly and device manufacturing, among other things, thanks to on-demand manufacturing. This allows for cost savings without the worry of delays associated with international business today. The company can feel confident it will be able to deliver on promises to consumers when on-demand manufacturing methods are used.

If you have yet to consider the use of on-demand manufacturing, now is the time to do so. Companies that employ this manufacturing method find they save money while better meeting the needs of their customers. This allows them to compete against major businesses in crowded industries while boosting their bottom lines.