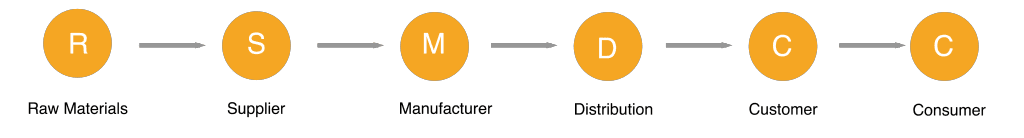

When You’re Tied Up In Supply Chains, You Need A Strategy

According to estimates by supply chain management organizations, the global supply chain market is worth more than $10 trillion a year. In short, it’s an enormous business, consuming some 6 percent of total world GDP, more than military spending and education combined. Getting our goods from one location to another is just really, really expensive.

As a company, managing your supply chain, organizing shipments and coordinating your efforts with other companies takes a lot of planning and effort. Here’s how to execute a great supply chain strategy without getting tied up in knots.

Get Better At Returns

Even in the most solid of supply chains, there’s a risk that either you or those further down the chain will receive goods they don’t want. This is an inevitable part of business and something which can never truly be eradicated. But it can become costly, especially if you don’t have the processes in place to reprocess or return items quickly.

Photo courtesy of Wikimedia Commons

Returns management should be a major focus. You need to inform all staff on a standardized return process so that if a return is required, it can be dealt with as quickly as possible without imposing further admin costs. With a good returns policy in place, your company can stand to benefit too. If you notice the same items coming back to you, again and again, you can collect data and use that information to improve your processes. Collecting proper records of returns helps to reduce defects and deliver a better quality product to your clients.

Monitor The Performance Of Vendors

Photo courtesy of David Pogrebeshsky via Wikimedia Commons

As a business, you also depend heavily on the performance of your vendors. If they continually make late shipments or fail to supply adequate products, it can have a knock-on effect on your business. Making sure that your vendors are regularly monitored is essential. Monitoring provides you with direct evidence of their performance and allows you to target specific issues of concern. Today’s modern vendor management software provides all this information on an easy-to-understand dashboard, allowing you to see their performance in real time.

Improve Your Distribution Network Through Standardisation

If you’ve ever watched a large commercial logistics operation at work, you’ll have noticed something: everything is standardized. The reason for this is that standardization makes things predictable and easy to manage. Having the same model of truck, or the same kind of docking bay at a warehouse helps keep maintenance costs low and predictable. If you need a particular kind of truck, you can find a dealer here. Utilising the same equipment across your entire fleet allows workers and drivers to use any machinery that happens to be available without having to be retrained.

Use Data At Every Stage Of The Process

Businesses are beginning to realize that data holds the key to greater efficiency and profits. With the right data collection methods, you’re able to collect information about precisely what’s in your inventory, what’s on its way to your warehouse or facility, and what needs to be shipped in the next hours, days or weeks. The gives you an unprecedented ability to control and manage your stock and provides you with clear guidelines about which jobs have to be done by when.

Reduce Waste, Shrinkage, And Fraud

Supply chains aren’t impervious to human error or malicious acts. They can be exploited by criminals within your organization, or become the victims of accidents. Some companies never fully investigate leakages like this, while others make a point of it. A leak in your supply chain could ultimately wind up costing you a lot of money. That’s why leading companies always make sure that the numbers reported in their software matches up to the figures after a physical count.

The best way to do this is to use scanning technology. Rather than have workers go out and manually count all the items in your inventory (with all the human error associated with that process), it’s much better to count items both in and out of your facility so that you can isolate problems in your supply chain. Running a tight ship will quickly tell you whether shrinkage problems are arising upstream or downstream from your facility. Once this happens, you can then pass on your data to the affected parties and help them resolve any security issues they may be having.

Automate Everything

Automation technology has come on leaps and bound in recent years. The annual demand for tactile robots is doubling, and by 2020, the market for robots will be nearly 10 times what it was in 2010. With so many robots coming onto the market, the cost of automating supply chain processes is going to fall dramatically: in fact, it is already.

Currently, the majority of robots are software-based. They do things like buy inventory automatically if levels start to fall, negating the need for human administrators. They’re also able to monitor inventory levels and issue warnings if levels fall too low and production is jeopardized.

In the future, robots will become an increasingly important part of the entire supply chain process. Driverless trucks will deliver payloads to robotic warehouse robots, which will then ferry components to their designated areas. The only job for humans will be to supervise the process, and fix the robots when they go wrong.

Get Your Team To Understand The Cost Of Managing A Supply Chain

A supply chain is an interdependent economic construct. Each element in the chain depends, indirectly, on the costs imposed by every other link. Although it is difficult to communicate across companies and coordinate, getting your own team to cooperate on matters of cost is a lot easier. Make sure that senior managers in your company are talking to each other and understand how costs they impose on their part of the supply chain impacts other departments. Knowing exactly where your business is spending money is a surefire way to improve the performance of parts of the business which are not so cost-sensitive. Having a central database of departmental costs across your entire company will make it easier for you to streamline your operations.

StrategyDriven Podcasts focus on the tools and techniques executives and managers can use to improve their organization’s alignment and accountability to ultimately achieve superior results. These podcasts elaborate on the best practice and warning flag articles on the StrategyDriven website.

StrategyDriven Podcasts focus on the tools and techniques executives and managers can use to improve their organization’s alignment and accountability to ultimately achieve superior results. These podcasts elaborate on the best practice and warning flag articles on the StrategyDriven website.

Marshall Fisher, co-author of

Marshall Fisher, co-author of

Joel Roth, author of

Joel Roth, author of