Cost-Effective Benefits of Investing in a Desktop Extruder for Your Small Business

Reduced Maintenance Costs

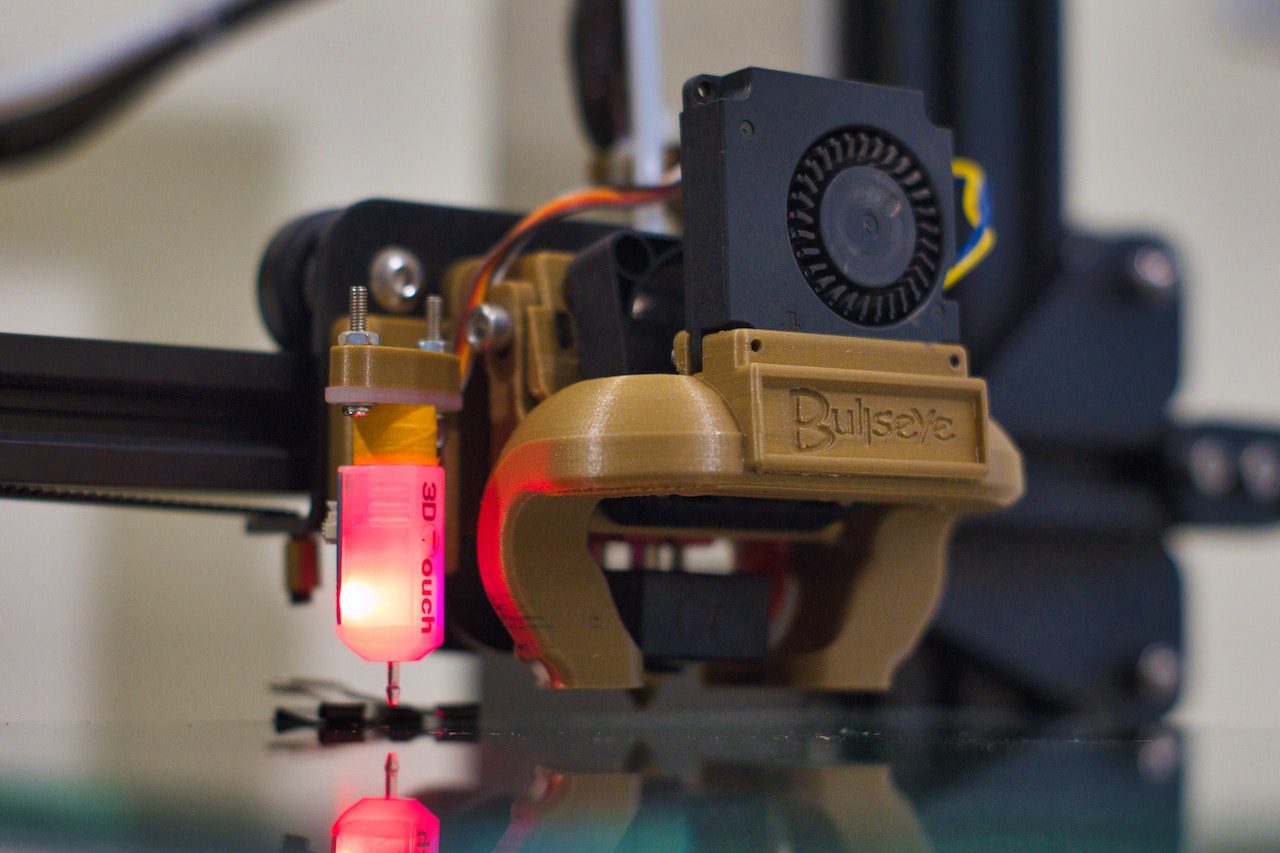

An extruder pushes heated filament through a print head to create the 3D-printed object. Using a ReDeTec ProtoCycler dual-extruder system allows two different materials to be used simultaneously and eliminates the need to change the filament. This reduces downtime by allowing production to continue while the machine is printing. However, the dual-extruder system adds a little weight to the printer. In addition, many printers with a dual-extruder system require more maintenance than those with a single extruder. This is because the print heads can overlap during printing, and the two prints must be carefully aligned. This requires more precise calibration of the digital model and is more complicated than standard single-extruder devices.

Increased Productivity

An extruder machine can recycle shredded 3D printed waste (failed prints and supports) into new filaments for your printer. This reduces the amount of plastic waste by up to 50% and can save you money in the long run. Moreover, making your own 1.75mm or 3.0mm 3D printing filament with a desktop extruder is easy. This doubles your productivity, allowing you to print complex pieces with hydrosoluble supports and multiple materials for more durable parts in less time. It uses two independent extruders controlled by stepper motors and planetary gears, enabling you to make twice as much material with half the effort. It can also process a range of thermoplastics, including PLA grades optimized for 3D printing, ABS, PETG, and PP.

Lower Material Costs

In many 3D printers, the same model material is used for the print and the support structures, which can be challenging to remove in post-processing. A desktop extruder enables you to use different materials for these structures, reducing the overall labor cost and increasing design freedom. With a filament extruder, you’ll have a reliable source of quality printing material. You won’t have to rely on unreliable online sellers; you can always have your favorite filament color available when needed. The extruder screw has been adapted to process shredded plastics from 3D printer waste (PLA grades optimized for printing, ABS, and PETG). The system can also extrude other polymers, such as nylon and PE, in pellet forms. This helps to reduce your printing costs and protects the environment by eliminating redundant plastic pollution.

Enhanced Productivity

A desktop extruder allows you to produce your filament quickly and accurately. It also allows you to print with various materials and colors while reducing waste. In addition, you can print multiple parts at once with a dual extruder and print with different nozzle sizes simultaneously for more substantial prints. This increases productivity and reduces the time required to complete a 3D print job. In addition, the IDEX extruder features two independent extruders that can be controlled independently from each other to avoid cross-contamination and maximize efficiency. This ensures that you will have a consistent output without any wasted material. It can also process a variety of plastics in pellet form, including various PLA grades (optimized for 3D printing), ABS, PETG, and PP.