4 Cutting-Edge Tools for Manufacturing Success

The manufacturing industry can be a competitive one, which is why it’s so important for business owners to be as efficient and productive as possible – the better you (and your team) work, the happier your clients will be. Happy clients means return clients and good word of mouth, which can boost your profits and make you much more successful.

One of the best ways to ensure you’re efficient and productive in your manufacturing business is to have the most cutting-edge tools to help you. With that in mind, here are some ideas to consider. Read on to find out more.

Automated Conveyor Systems

Conveyors and conveyor belt equipment have been part of the manufacturing process for a long time – since the start, perhaps. Of course, everything was done by hand back then, which meant a slow, inefficient, and potentially even dangerous process. Thankfully, things are very different today, and conveyors like those at Machinery Partner, are much safer and do the job much better.

In fact, the most cutting-edge conveyors are the best yet because they’re usually equipped with sensors, actuators, and other sophisticated controls that can be much more adaptable. They can even change their speed, or how they’re working depending on the amount they need to carry – and rather than an operator having to do it, it’s an automated process. That makes removing waste, for example, much more efficient, ensuring your business runs as smoothly as possible.

Cobots

If you’ve never heard of cobots, don’t worry – it’s just a term that means ‘collaborative robots’, and these can be a fantastic addition to your manufacturing business, ensuring you’re absolutely on the cutting-edge of new technology at all times.

These machines are designed to work with their human counterparts, so you don’t need to worry that your team won’t like them (they’re not taking human jobs), and because they’re new and improved, they don’t have to be kept in cages for safety like traditional manufacturing robots tend to be. They’re massively versatile and can do all kinds of different jobs, including potentially fixing machines more quickly and safely than a person could.

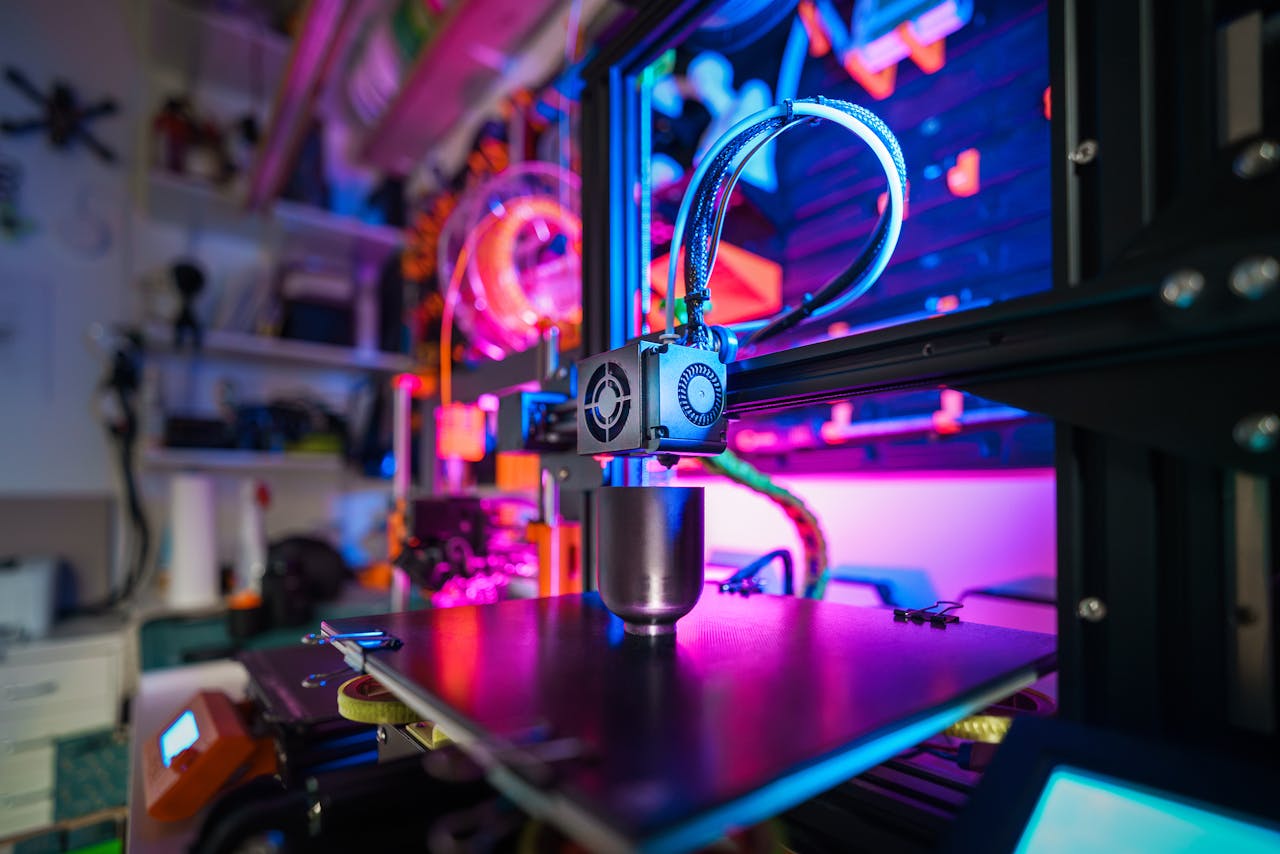

3D Printing

What is additive manufacturing? Well, you probably already know, because it’s another term for 3D printing, which is a fantastic cutting-edge tool that can be ideal for the manufacturing industry.

If you’re not sure what it can do, 3D printing can make patterns and information and use them to make components quickly and precisely. You need to work out the digital design to be used, and then feed it to the printer, which will then ‘print’ what you need. There are a number of benefits to using a 3D printer, but some of the biggest are reduced costs and faster production.

Predictive Maintenance Software

Finally, predictive maintenance software is another piece of excellent cutting-edge technology that you can use to great advantage in your manufacturing business. Just think of all the tools and pieces of equipment that come together to do what needs to be done for you – and just think of how much downtime you lose when something goes wrong or something just needs to be routinely checked.

With predictive maintenance software you can reduce downtime by knowing in advance when something needs to be serviced or a component has to be changed – you can plan things out so that downtime is minimized or even done away with altogether!